wire edm machine working principle

Makino is the world leader in wire EDM. It is used for producing hole size less than 01 mm.

What Is Edm Machining Wire Edm 101 Sans

Wire EDM machining can cut through.

. The supply of dielectri. It is not the most popular CNC machining. Used for die sinking or die manufacturing.

The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task. A wire cutter also known as a wire EDM is based off the same principle as a traditional EDM. Ad Double cutting speed without increasing wire consumption with our latest model.

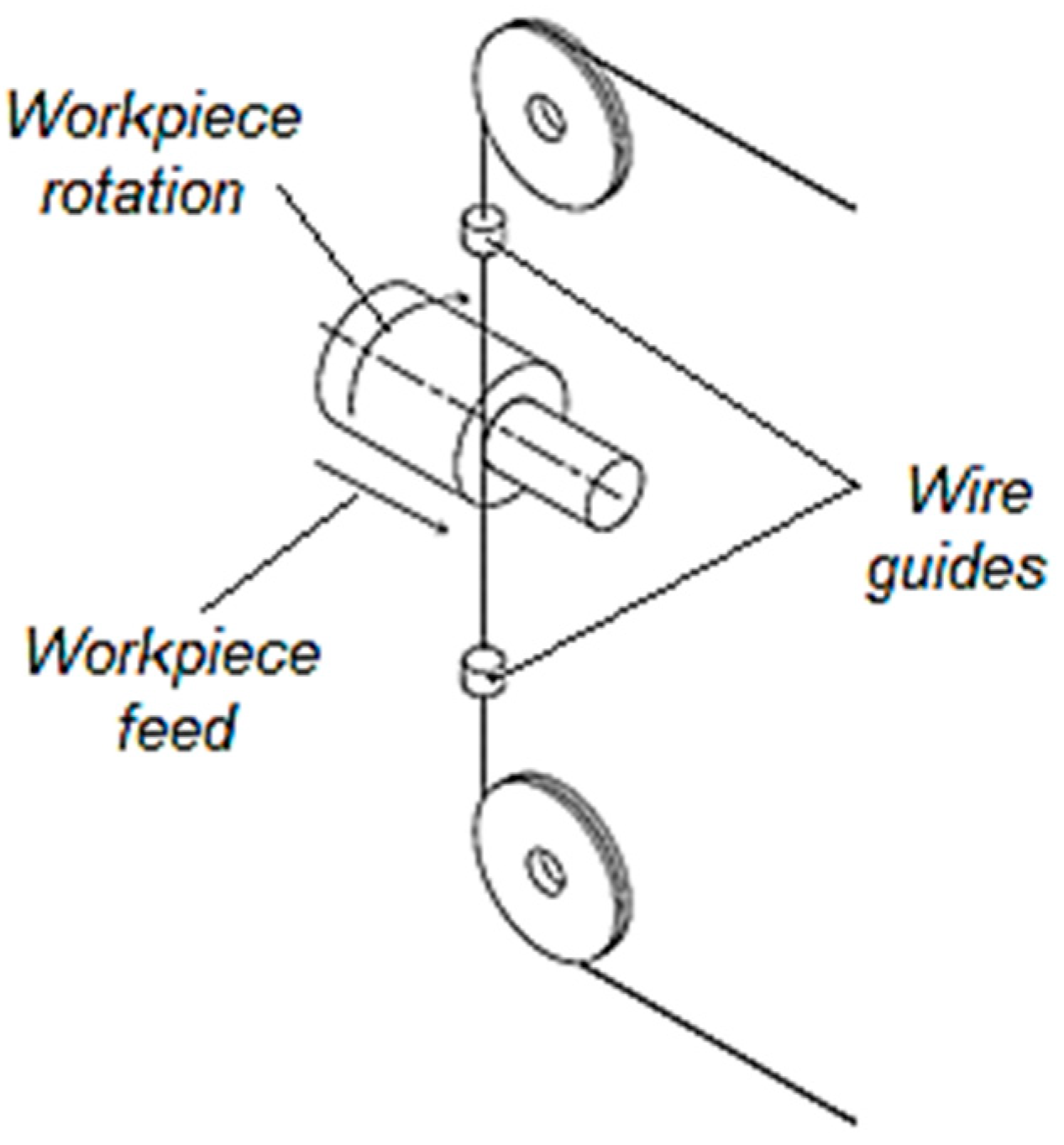

There are many different specialised types of EDM machine but they generally fall into three separate categories. According to the form of the tool electrode and the relative movement between the workpiece and the workpiece the EDM. Ad Double cutting speed without increasing wire consumption with our latest model.

A wire EDM machine can. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always. Working Principle and Performance of Wire Electrical Discharge Machining Abstract.

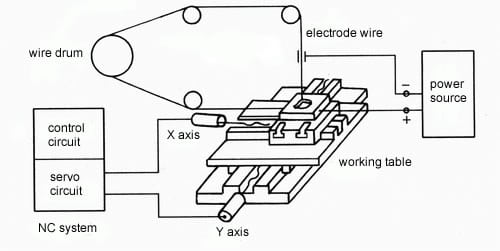

Wire edm machine working principle. Wire EDM Tooling system is also known as wire cutting its basic working principle is the use of continuous moving electrode wire the workpiece cutting molding. Holes in the air brakes or.

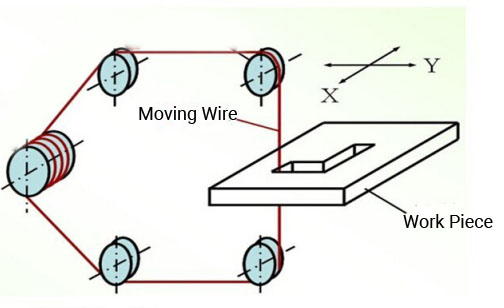

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. It is suitable for thermoelectric. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that.

The Basic Principle Of WEDM. Here are some applications of Electrical Discharge Machining. Electrical Discharge Machining Working Principle What is the basic principle of EDM and how the material is removed in this process.

A small gap of a calculat. A major advantage of wire EDM over conventional EDM is that the continuous supply of wire minimizes the wear that occurs with a fixed electrode. No actual contact is made between the wire and.

Wire cut EDM and sinker EDM both employ the principle of electrical discharge machining what are the differences between them. Die sinker or ram EDM. For quality parts delivered on time choose Xometry cnc machining services.

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting. Makino is the world leader in wire EDM. Ad Full suite of CNC machining services including the latest in wire EDM machining.

The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as electrode and deionized water as. Electrical discharge machining EDM is a. The term EDM stands for Electrical Discharge Machining.

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Find Suppliers Processes Material

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Mas 865 How To Make Something That Makes Almost Anything

Edm Machine Video Edm Molding Professional Performance

Wire Electrical Discharge Machining Also Call Wedm Its Working Principle Is The Use Of Continuous Moving Thin Wire Called Elect Cool Things To Buy Cnc Metal

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Edm Find Suppliers Processes Material

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Edm Cutting Process With High Precision Ruhlamat

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Mechanical Principle 43 3q Machining Video In 2022 Steel Furniture Design Steel Furniture Mechanical Engineering Design

3 Schematic Diagram Of Wedm System Download Scientific Diagram